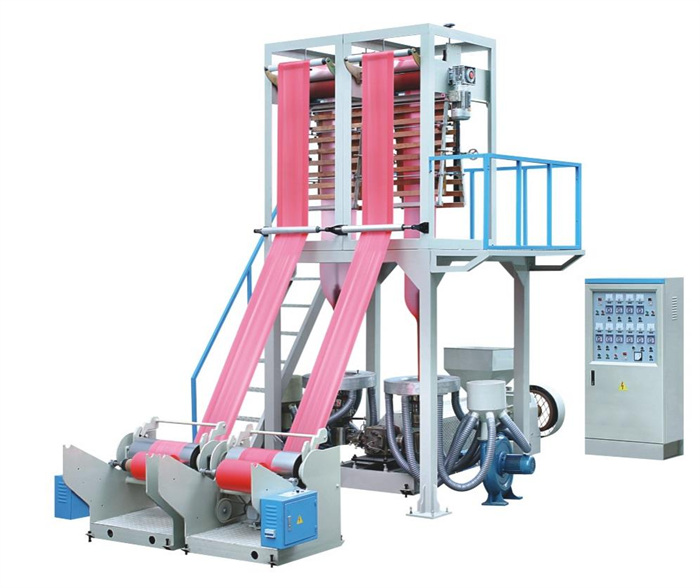

Main Technical Variables:

|

Specification |

|

|

Model |

KDJ-45 |

|

Material |

HDPE, LDPE |

|

Max. Film width(mm) |

400 |

|

Film thickness (mm) |

0.01-0.1mm |

|

Pinch roller width(mm) |

500mm |

|

Max. extrusion output |

30-35kg/hr |

|

Extrusion unit |

|

|

Screw diameter(mm) |

Φ45 |

|

L/d ratio |

28:1 |

|

Gearbox |

133 |

|

Screw material |

38CRMOALA , Taiwan design |

|

Barrel material |

38CRMOALA ,Taiwan design |

|

Barrel’s cooling fan |

250w*2 |

|

Barrel heater capacity(kw) |

5 |

|

Driving motor |

11kw with inverter |

|

Barrel thermo control(zone) |

3 |

|

Filter changer thermo zone |

1 |

|

Extrusion die |

|

|

Die size |

Φ50 |

|

Thermo control(zone) |

1 |

|

Air ring |

Φ600, double vent air ring |

|

Cooling blower(kw) |

2.2 |

|

Take-up unit |

|

|

Roller width of take up(mm) |

Φ150×500mm |

|

Take-up motor |

1.5kw |

|

Take-up speed(m/min) |

10-60 |

|

Bubble basket |

Bakelite type |

|

Winding unit |

|

|

Winding type |

Surface friction single winder |

|

Winding motor((kg.m) |

0.3kg/m (+reducer) |

|

Winding speed(m/min) |

10-60 |

|

Voltage |

380v,60hz,3phase |

|

Cover dimension(m) |

3×2.5×3.5 |

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

All of our machines with 1 year guarantee.

Our machines are well favoured by customers due to easy operation, perfect performance, easy maintenance good & prompt after sale service. If you need intallment or training service,we can send engineer to your country,help you intall machines,training your workers to use machine(you need pay double way air tickets,salary,food,hotel for our eningeer).

Install machines in Saudi Arabia.

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

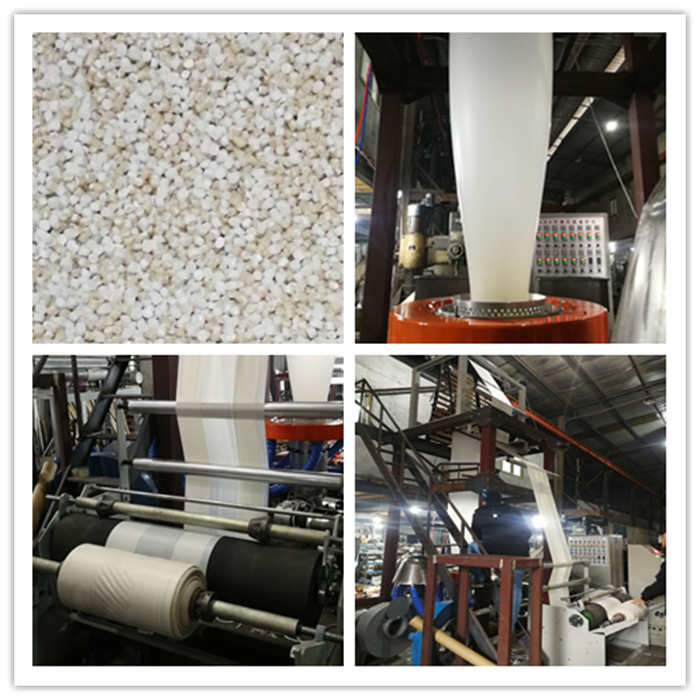

Extrusion Film Extrusion use Polyethelene,such as Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP). Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

Welcome to our website! Please feel free to send us your inquiry in detail, we will reply you as soon as possible.