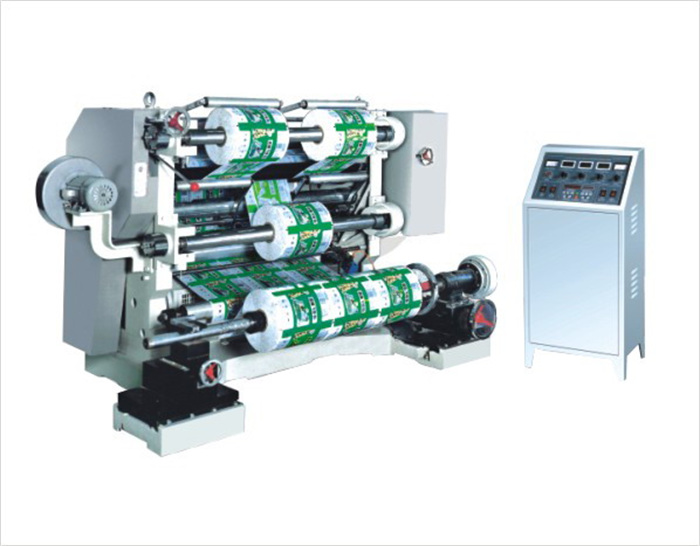

vertical slitting machine is suit for slitting and rewinding roll materialssuchas BOPP, PET, CPP, CPE, PVC, aluminum foil and paper, etc. and can cut edge, separate and cut material according to different requirements during production.Slitting machine equipe edge positon control and automatic tension controller.

vertical slitting machine is suit for slitting and rewinding roll materialssuchas BOPP, PET, CPP, CPE, PVC, aluminum foil and paper, etc. and can cut edge, separate and cut material according to different requirements during production.Slitting machine equipe edge positon control and automatic tension controller.

Feature:

1. Suit toLDPE film,HDPE film,LLDPE film,BOPP film,PP film,PET film,paper,

2. inveter controlslitting machinespeed,save power and ECO,save cost

3. Film width 100mm-1300mm

4. Edge positon control

5. Automatic tension controller

6. Screw material is 38CrMoAl,can use long time

7. Warrant is one year,machine can running nonstop,24 hours a day, 7 days a week

8. Machine with simple design,easy operate

9. Machine is economic design,suit for new beginer or starters

10. Machine power 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...)

11. Afford after sale service,can send engineer to buyer factory,to install machine and afford training service.

12. We are welcomed customersCustomized machines or OEM design.

|

Type |

LFQ-700A |

LFQ-1100A |

LFQ-1300A |

|

Max.Width of Mother Roll |

700mm |

1100mm |

1300mm |

|

MAX.Diameter of Mother Roll |

Φ600mm |

Φ600mm |

Φ600mm |

|

Width of Final Roll |

30-600mm |

30-600mm |

30-600mm |

|

Material |

BOPP,OPP,CPP,PET,LDPE,HDPE,Paper |

||

|

Slitting and Rewinging Speed |

5-160m/min |

5-160m/min |

5-160m/min |

|

Tolerance of EPC |

<±0.5mm |

<±0.5mm |

<±0.5mm |

|

Total Power |

2.7kw |

3.5kw |

3.5kw |

|

MachineWeight |

1200kg |

1500kg |

1800kg |

|

Machine size |

2000×1110×1400mm |

2400×1110×1400mm |

2600×1110×1400mm |

|

Power Voltage |

220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

||

|

Material Core Diamater |

58mm,76mm |

||

|

Machine Working Time |

24 hours * 7 days |

||

|

Warranty |

1 year |

||

|

Technical Assistance |

Engineers available to service machinery overseas |

||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

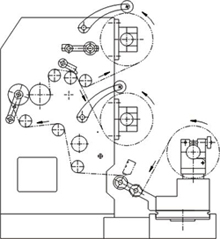

Slitting machine operation:

When there is a film on the slitter, when using the vacuum filming station, the filming station is first started to the working position, and the film on the drawing roller di-drawing roller is manually flattened and the upper vacuum pump is started. Suck the film, make the film flat on the filming table, attach the double-sided tape and cut off the excess film under the tape, flatten the film on the unwinding frame and start the lower vacuum pump to make the film flat and absorb the tape. Upper the paper layer and flatten the adhesive film, the joints should be neat, wrinkle-free, then turn off the upper and lower vacuum pumps, and open the filming station to not working.

Our Main parts cooperator as following brand,but standard parts all made from China.

Welcome to our website! Please feel free to send us your inquiry in detail, we will reply you as soon as possible.