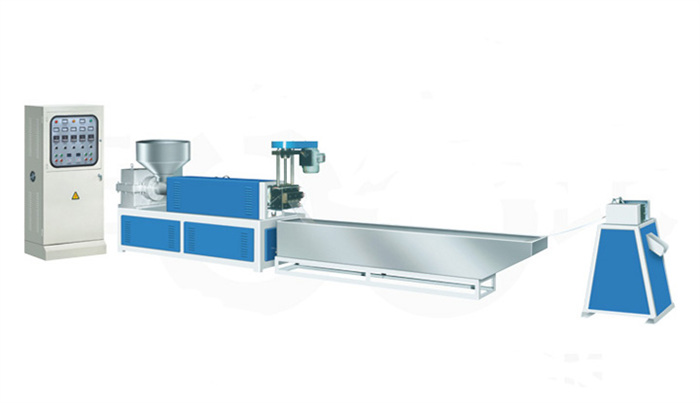

PET recycle machine suit to recycle plastics products,as HDPE,LDPE,and PP,etc.plastic recycle machine speed control by inverter,save power.

The granulating crusher uses adjustable speed motor.machine easy operate,high capacity.

PET recycle machine suit to recycle plastics products,as HDPE,LDPE,and PP,etc.plastic recycle machine speed control by inverter,save power.

The granulating crusher uses adjustable speed motor.machine easy operate,high capacity.

Feature:

1. LDPE,HDPE,LLDPE,PP material

2. Material shapes: film, bag and flake.

3. inveter control extruder speed,save power,ECO andsave cost.

4. extruder, pelletizing unit, water cooling unit

5. Warrant is one year,machine can running nonstop,24 hours a day, 7 days a week

6. Machine with simple design,easy operate

7. Machine is economic design,suit for new beginer or starters

8. Machine power 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...)

9. Afford after sale service,can send engineer to buyer factory,to install machine and afford training service.

10. We are welcomed customersCustomized machines or OEM design.

Service System(Plastic Granulating Machine):

· Pre-sale: we given client the details technician offer, sign the sales contract etc.

· In-sales: we supply the details layout, installation instruction, technician support for the clients;

· After sales: we arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

- We always up date the new technology to every customer

PET bottle recycling:

Post-consumer polyethylene terephthalate (PET) containers are sorted into different color fractions and baled for onward sale. PET recyclers further sort the baled bottles and they are washed and flaked (or flaked and then washed). Non-PET fractions such as caps and labels are removed during this process. The clean flake is dried. Further treatment can take place e.g. melt filtering and pelletizing or various treatments to produce food-contact-approved recycled PET.

Main Technical Variables:

|

Model |

SJ-90 |

SJ-100 |

SJ-110 |

SJ-120 |

|

Type Diameter of Screw Stem |

φ90 |

φ100 |

φ110 |

φ120 |

|

Major Diameter Ratio of Screw Stem |

L/D 20:1 -22:1 |

L/D 20:1 -22:1 |

L/D 20:1 -22:1 |

L/D 20:1 -22:1 |

|

Rational Speed of Screw Stem |

10-100r/min |

10-100r/min |

10-100r/min |

10-100r/min |

|

Main Motor Power |

22kw |

30kw |

37kw |

45kw |

|

Output |

68kg/h |

95kg/h |

120kg/h |

135kg/h |

|

Weight of overall(kg) |

2600kg |

2800kg |

3000kg |

3200kg |

|

Cover dimensions (l×w×h) (mm) |

4000×1500×1800 |

4000×1500×1800 |

4000×1500×1800 |

4000×1500×1800 |

|

Power Voltage |

220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

|||

|

Machine Working Time |

24 hours * 7 days |

|||

|

Warranty |

1 year |

|||

|

Technical Assistance |

Engineers available to service machinery overseas |

|||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Our Main parts cooperator as following brand,but standard parts all made from China.

¡Bienvenido a nuestro sitio web! No dude en enviarnos su consulta en detalle, le responderemos lo antes posible.