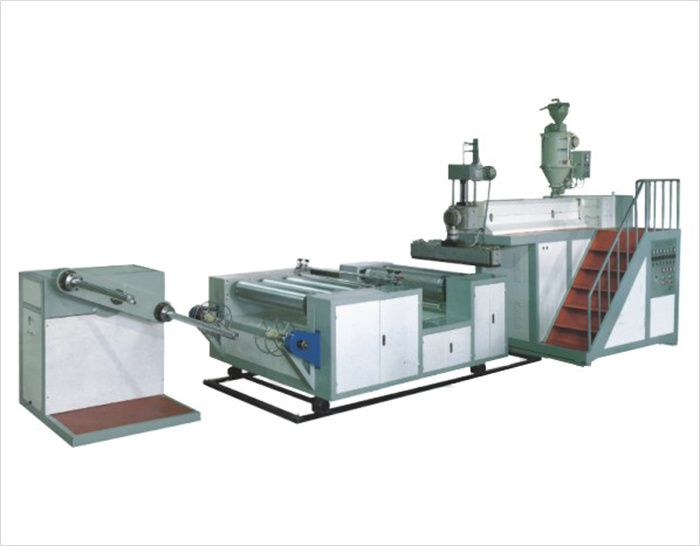

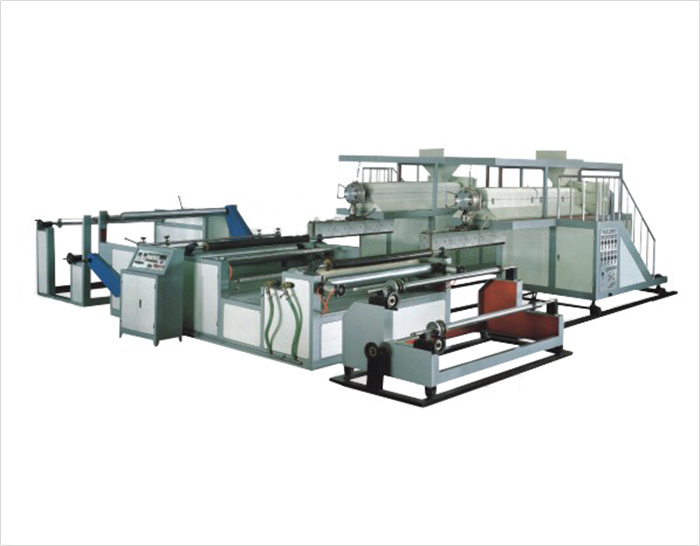

Polyetylene laminate aluminum foil four layers air bubble film machine also called air bubble wrap film extrusion,machine use Low Density Polyethylene(LDPE) proudce air bubble film.

Four Layers Air bubble film machine simple design,easy operate,design for 24 hours 7 days working.

Four LayersAir Bubble Sheets Machine;

Four Layers air bubble film extrusion line;

Four Layers air bubble film lamination line;

Four Layers air bubble film making line;

Four Layers air bubble film extrusion machine;

Four Layers air bubble film packge machine;

Four Layers air bubble film foil lamination machine;

Polyetylene laminate aluminum foil four layers air bubble film machine also called air bubble wrap film extrusion,machine use Low Density Polyethylene(LDPE) proudce air bubble film.

Four Layers Air bubble film machine simple design,easy operate,design for 24 hours 7 days working.

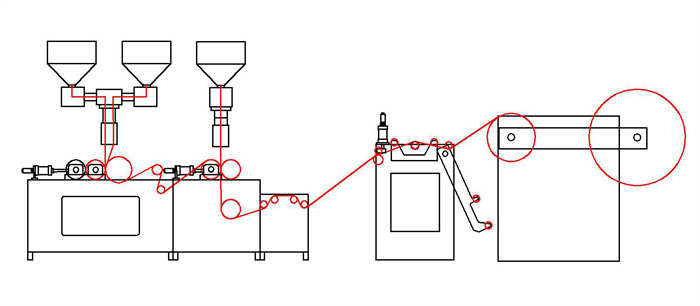

Air bubble film machine has 11 units:extruder,vacuum pump,air bubble forming unite,slitting unite,edge trimming unit,waste film collection unit,leveling unit,winding unit,air compressor,cooling system and electric control system. It can achieve the mechanotronics from raw material feeding from the charging barrel until the finished roll automatic control.

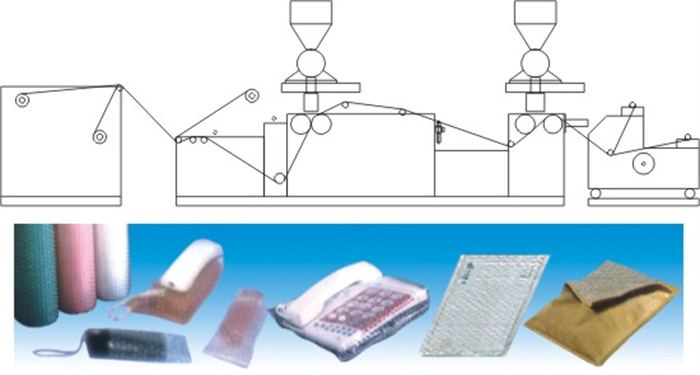

Air bubble film is filled with air,it is light,transparent, high resilience,with sound insulation, anti-vibration and anti-wear performance.Air Bubble Sheets Machine used in electronic,glassware, machinery, automobilespare parts,express envelope bag, instrumentation,ceramics,handicrafts,household appliances, bicycles, kitchens,furniture and lacquer products, glass products and precision instruments and other anti knock cushioning packaging.

1. Packaging solutions: Dust covers, bubble wrap etc. for fragile items like glassware, mirrors, picture frames, ceramics, chinaware, pottery, handicrafts etc.

2. Anti-static packaging covers

3. Packaging of consumer durables and white goods like TV covers, Refrigerator packaging, LCD / LED packaging etc.

4. Packing material for painted surface of components

The correct way to use of bubble film machine:

The bubble film machine (air cushion film machine) is regularly inspected, and the die is thoroughly cleaned every three months. The grease is replaced for various bearings. The lubricating oil is replaced once every six months, and the whole device is used every two years. Perform an overhaul.

Main Technical Variables:

|

Model |

KDPEG-1000 |

KDFPG-1200 |

KDPEG-1500 |

|

Raw Material |

LDPE,recycle material,masterbatch and additives materia |

||

|

Screw Diameter |

φ65mm+φ50mm |

φ75mm+φ60mm |

φ90mm+φ70mm |

|

Bubble film Max. width |

600mm |

1200mm |

1500mm |

|

Bubble Film Layer |

4 layers |

||

|

Bubble Film Color |

Transparent,Black,Red,White,blue…bag color changed by mastbatch |

||

|

Laminate film |

PE film,PET film,aluminum film,non woven film,Paper |

||

|

Output |

55kg/h |

70kg/h |

90kg/h |

|

Total power |

75kw |

82kw |

98kw |

|

L/D Ratio Of Screw |

28:1 |

28:1 |

28:1 |

|

Water Consumption |

0.5m3/h |

0.5m3/h |

0.5m3/h |

|

Machine Weight |

3.5 |

4.5 |

5 |

|

Power Voltage |

220V,380V,440V(Customized based on request (For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

||

|

Air Shaft Diamater |

without paper core ,58mm,76mm |

||

|

Machine Working Time |

24 hours*7 |

||

|

Warranty |

1 year |

||

|

Technical Assistance |

Engineers available to service machinery overseas |

||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Our Main parts cooperator as following brand,but standard parts all made from China.

¡Bienvenido a nuestro sitio web! No dude en enviarnos su consulta en detalle, le responderemos lo antes posible.