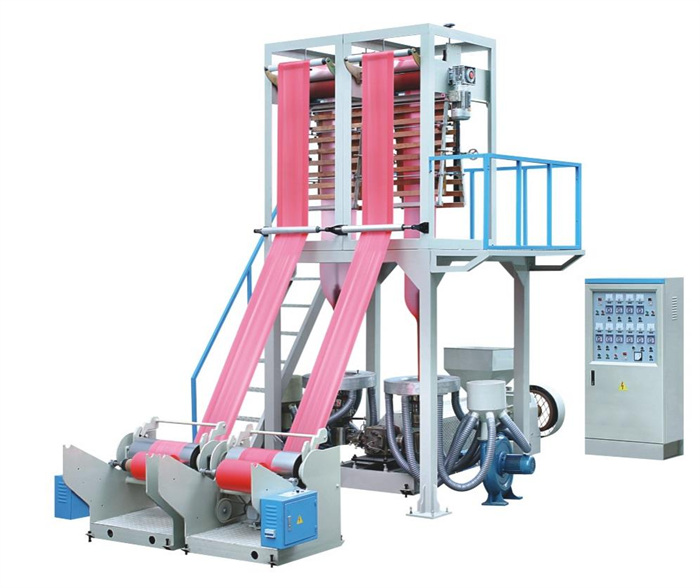

Film blowing machine connect 2 Colors GravurePrinting machine,can produce film and print film one line,save labour,save cost.Polyethylene film blowing machine is economic design,suit for newbeginer who look to start the film production business.

Film blowing machine connect 2 Colors GravurePrinting machine,can produce film and print film one line,save labour,save cost.Polyethylene film blowing machine is economic design,suit for newbeginer who look to start the film production business.

Film blowing machine produce high quality film,suit for general packaging products such asflat bag,T-shirt bags, supermarket bags,shopping bag,sachet water bag,packing film and many others.

GravurePrinting Connect with two colors printing roller and rubber roller,printing machine speed as same as film blowing machine speed.We can add printing machine colors as buyer request.

Here's how we should maintain the machine body in our daily life.

1. After the main engine is turned on, pay close attention to the operation of the main engine, timely adjust, correct, electrical instruments and controllers, observe whether there is any abnormality or damage, and make maintenance and replacement to ensure its normal operation.

2. The main engine gearbox and traction reducer should be refueled regularly, and the gear oil should be replaced (the oil level can reach the calibration line). The new machine should replace the new gear oil in about 10 days to ensure the normal operation of the rotating parts, prevent the operation difficulty and overheating damage, and check the tightness of the connecting parts to prevent the bolt from loosening.

Feature:

1. LDPE,HDPE,LLDPE virgin raw material, recycled material, CaCO3 compound, biodegradable material, masterbatch and additives materia

2. inveter control film extruder speed,save power,ECO andsave cost.

3. Film thickness 0.01mm-0.1mm

4. Film width 100mm-1000mm

5. Film suit forvegetable bag,mailer express bag,flat bag,T-shirt bag,trash bag,cloth bag and for package.

6. Film blowing machine connect Rotogravure printing machine in line

7. Rotogravure printing machine have 1 color,2 colors,3 colors,4 colors,5 colors,6 colors…

8. Screw material is 38CrMoAl,can use long time

9. Warrant is one year,machine can running nonstop,24 hours a day, 7 days a week

10. Machine with simple design,easy operate

11. Machine is economic design,suit for new beginer or starters

12. Machine power 220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...)

13. Afford after sale service,can send engineer to buyer factory,to install machine and afford training service.

14. We are welcomed customersCustomized machines or OEM design.

Optional Equipments:

1)Auto Loader

2)Air Compressor

3)Rotary Die Head

4)Double Side Winder(Back to back winder)

5)Up and Down

6)Embossing Cylinder

7)Air Shaft

8)Masterbatch Dosing device

9)Automatic Winder Changer

10) Corona treatment

|

Model |

SJ50- ASY2600 |

SJ55- ASY2800 |

SJ65- ASY21000 |

|

Blowing Flim Width |

600mm |

800mm |

1000mm |

|

Printing Width |

600mm |

800mm |

1000mm |

|

Printing Length |

191-1200mm |

191-1200mm |

191-1200mm |

|

Printing Color |

2 colors |

||

|

Mterials |

LDPE,HDPE,LLDPE,recycle material |

||

|

Film Color |

Transparent,Black,Red,White,blue…bag color changed by mastbatch |

||

|

Usage |

Plastic Shopping Bag,T-shirt bag,trash bag,packing film,table cover,shrink film |

||

|

Screw DIA |

50mm |

55m |

65mm |

|

Screw L/D Ratio |

28:1 |

28:1 |

28:1 |

|

Blow Film Motor Power |

11Kw |

15Kw |

18.5Kw |

|

Max Extruded Quantity |

35kg/h |

50Kg/h |

65Kg/h |

|

Film I lead DIA |

φ60、φ 100 |

φ80、φ150 |

φ100、φ200 |

|

Blow Flim Thickness |

0.01-0.10mm |

0.01-0.10mm |

0.01-0.10mm |

|

Total Power |

28Kw |

32Kw |

40kw |

|

Weight |

3.5T |

4T |

5T |

|

Dimensions (m) |

6x2.4x4 |

6.2x2.6x4.3 |

6.4x 2.8x 4.8 |

|

Power Voltage |

220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...) |

||

|

Material Core Diamater |

76mm |

||

|

Machine Working Time |

24 hours * 7 days |

||

|

Warranty |

1 year |

||

|

Technical Assistance |

Engineers available to service machinery overseas |

||

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

All of our machines with 1 year guarantee.

Our machines are well favoured by customers due to easy operation, perfect performance, easy maintenance good & prompt after sale service.

If you need intallment or training service,we can send engineer to your country,

help you intall machines,training your workers to use machine(you need pay double way air tickets,salary,food,hotel for our eningeer).

Install machines in Saudi Arabia.

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

Extrusion Film Extrusion use Polyethelene,such as Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP). Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company

¡Bienvenido a nuestro sitio web! No dude en enviarnos su consulta en detalle, le responderemos lo antes posible.